Apple Inc. (NASDAQ:AAPL) continues its strong focus on sapphire creation and use with a patent application published today by the U.S. Patent and Trademark Office (USPTO) related to continuously growing sapphire crystal. This process, the application shows, would not produce a single boule from which screens were sliced, but a “sapphire ribbon” that would advance out of the crucible even as additional sapphire material continued to be generated behind it. This important technique could increase the speed of production considerably, making Apple’s massive sapphire plant even more efficient and cost effective.

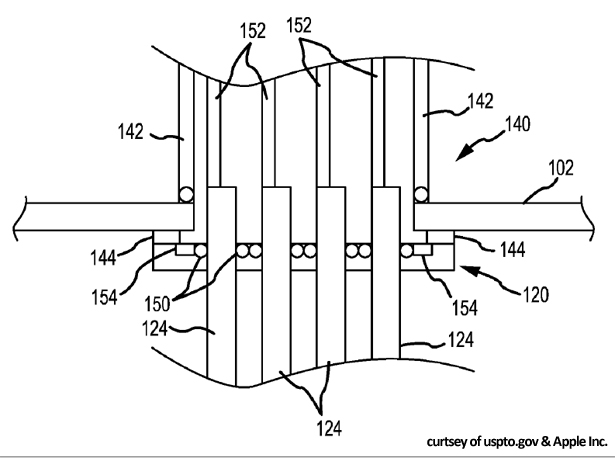

As with many well developed patent applications, the “Continuous Sapphire Growth” concept details several possible approaches to the process. All involve a special crucible with an opening, in either the side or top, through which the sapphire ribbon can be pulled. Regularly spaced inlets would enable silica to be fed steadily into the furnace hot interior of the crucible in order to keep the sapphire generating process ongoing.

The system would use rollers to pull the sapphire ribbon either horizontally or vertically upwards, depending on the exact configuration Apple’s (AAPL) engineers eventually opted for. At least one roller would also be a torque sensor that ensured the proper amount of force was being applied to the ribbon to keep it moving but not break it. A light-based inspection unit mounted on the outer skin of the crucible would scan the ribbon as it emerged and alert personnel to any defects it detected during the scanning process.

As the ribbon moved on, it would encounter a cutting mechanism that would slice it into usable panes. Undoubtedly, additional cutting of these panes would be needed to fit them to various device display sizes, but this is the point where the sapphire would no longer remain in a physically continuous state. Two methods of possibly cutting the material are indicated – scribing and breaking with a mechanical cutter, or slicing with a laser cutter.

The United States Patent Application, Number 20140090592, was originally filed on September 28th, 2012. The inventors of record are Dale N. Memering and Scott A. Myers, with Apple as the assignee. Mr. Memering is a University of Waterloo graduate who worked for Christie Digital Systems and Quadro Engineering before landing his current job as a Product Design Engineer at Apple. His name has appeared on 9 different patent applications, the oldest in 2012, most of which appear to relate to sapphire production. Mr. Myers is a graduate of the University of California’s Berkeley campus and has worked for Nokia as well as Apple Inc. (AAPL) in the past.

Apple Inc. (AAPL) continues its massive and innovative push towards making sapphire crystal an integral, if not defining, part of its product ecosystem. Each new patent application reveals additional ways of introducing fresh efficiencies into sapphire production, thus lowering its cost and making the scratch-proof material a likely component of any future Apple releases.